This is a great option for high-end resort areas, mountain towns, etc.

PANELIZED KIT PRICING (SHIPPING NOT INCLUDED)

SUBMIT READY FLOOR PLANS, $14,900

ENGINEERING AND BUILDER PACKET

* Currently only available in Utah, Idaho, Colorado, Wyoming, Montana, Arizona and Nevada.

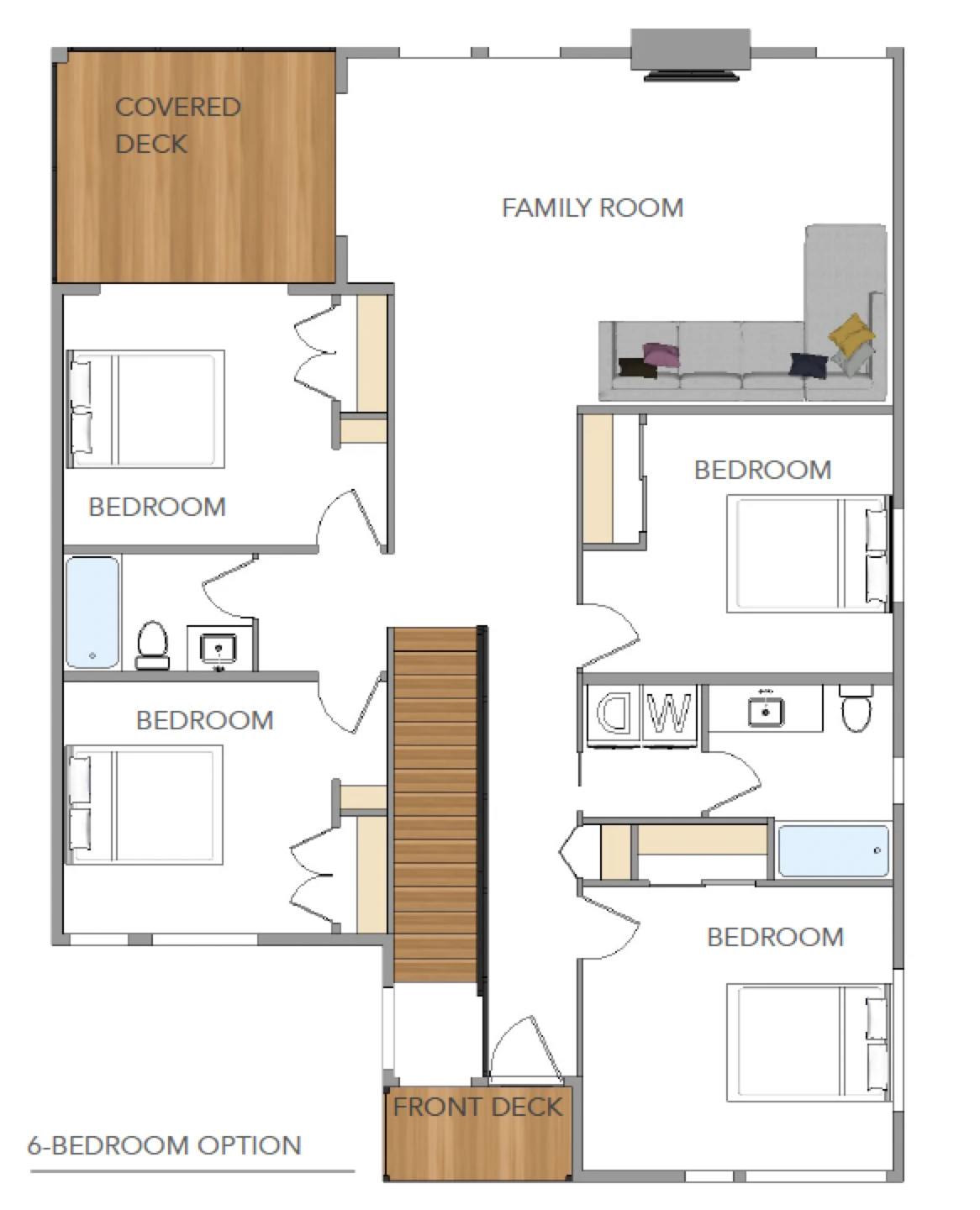

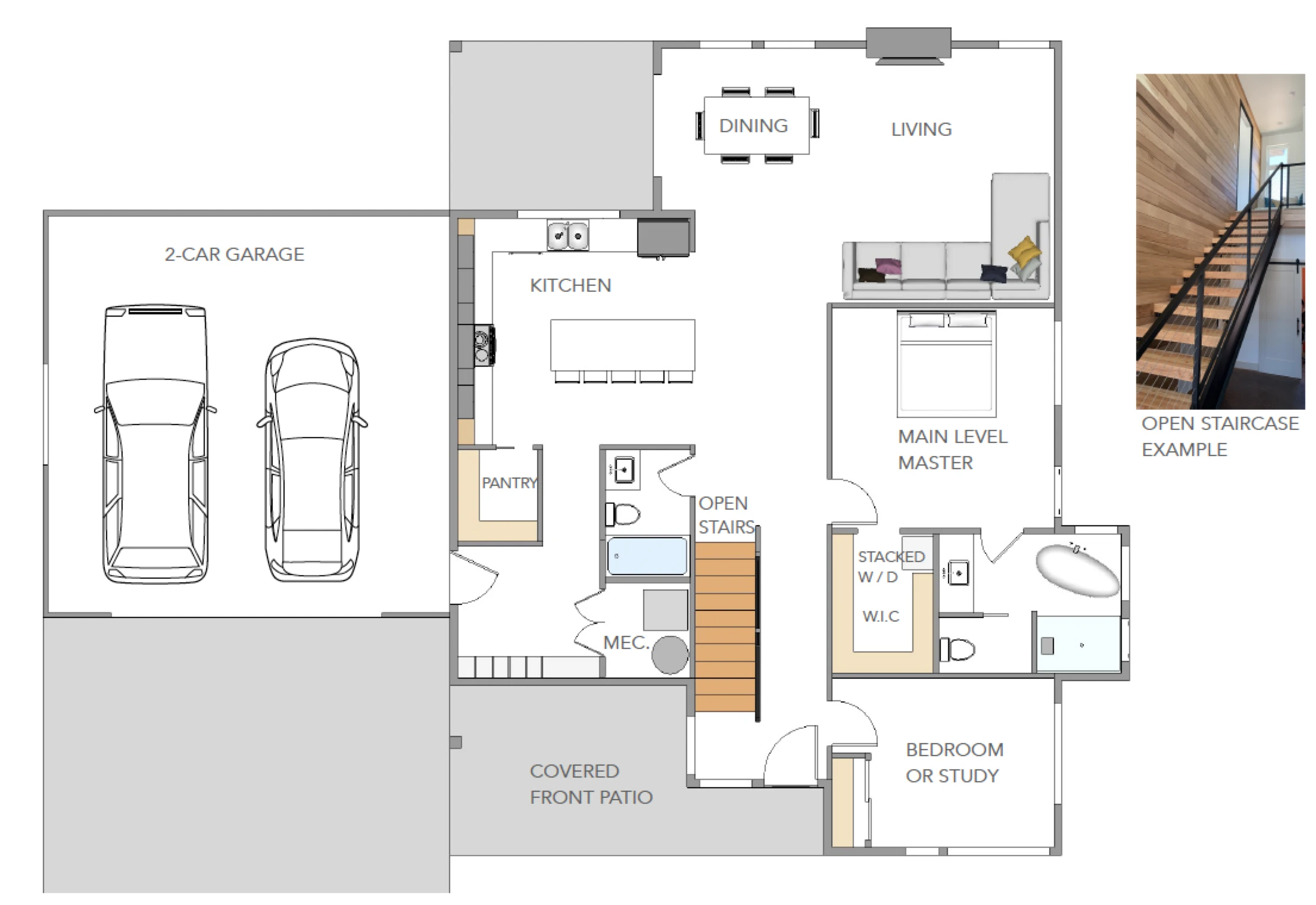

1. Detailed floor plans. The floor plans are designed by builders who understand how to reduce waste and simplify the construction process.

2. Structural engineering. Designed specifically for your location – snow loads, seismic, frost depth, etc.

3. Res-check energy submittal. Energy compliance information that may be required by the building department.

4. Site plan. This is specific for your lot (geotechnical and soils engineering not included).

5. Material list and “take-off” sheets. We provide a material list for the items needed to build your home.

6. Scheduling checklist. A complete checklist to help you keep track of and organize the tasks to build your home.

7. Sub-contractor work-order sheets. Sub-contractor contracts, work orders and scope of work documents.

8. Cost breakdown template sheets. Document templates Required by your bank to get construction financing

ITEMS INCLUDED:

1. Pre-framed exterior wall panels.

2. Pre-framed interior wall panels.

3. Pre-framed stairs and other structural framing components.

4. Weatherproof sheathing tape or Tyvek house wrap.

5. Pre-cut structural beams and posts.

6. Roof panels or engineered trusses.

7. Lumber to finish the trusses and roofing –sheathing, blocking, sub-fascia, etc.

8. High temp, Ice and water shield underlayment for complete roof waterproofing.

9. All labor to set the panels and complete the framing and roofing dry-in for your home.

WINDOW AND EXTERIOR DOOR PACKAGE ($36,850)

Anderson 100 series black composite windows made of Fiberex composite materials. 2x stronger and 12X thicker finish than painted vinyl.

WPC SIDING PACKAGE ($7.5O PER SQ FT)

WPC Siding (wood plastic composite) is made of real wood chips and recycled thermoplastics. This provides a natural wood look that is maintenance free, so you never need to re-stain or paint.

Traditional onsite construction is outdated. It’s slow, wasteful and less efficient than modern prefab construction methods. The advantages of our construction method are:

1. Built Faster – Generally our kit homes can be built 3x faster than a standard site-built home.

2. Less Stress – Building a house is stressful. With a panelized kit, we try to streamline the entire process from design and engineering, to setting the panelized kit, to providing documents needed to manage the rest of the construction process and finish your home.

3. Precision-Built –Panels and components are built out of the weather, in a controlled environment, using precision equipment. The result is a better-built home.

4. Sustainable – We use materials in a much more efficient manner. The result is 80% less waste than a standard site built home. This also helps keep a cleaner, more organized jobsite during construction.

PAYMENT 1: Design deposit for detailed floor plans and engineering.

PAYMENT 2 : 45% - To purchase all materials, get in the production schedule and begin construction in the factory.

PAYMENT 3: 45% - When the panelized kit is completed and ready to ship.

FINAL PAYMENT: 10% - When the panelized kit is assembled, and our scope of work is completed.

STEP 1: DESIGN AND ENGINEERING.

After you choose a floorplan, you pay the deposit for the floor plans and engineering. We then contact your local building department to determine the design and engineering requirements for your specific building lot. Engineering requirements are specific to your location depending on snow loads, frost depth, wind loads, seismic requirements, etc. We then complete the plans and engineering specific for your building location. We send you complete, submit-ready floor plans, stamped structural drawings, engineering calcs, construction documents, work orders, cost breakdown sheets, sub-contractor checklists, etc.

STEP 2: ONSITE WORK.

After the building permit is issued, your local contractor will complete all the onsite work: excavation, foundation, utility line stub-in’s etc. We provide the floor plans, engineering and instructions for the foundation and onsite work.

STEP 3: SHELL KIT INSTALL.

When your onsite work is completed, we ship and assemble the shell kit. This includes everything so that the structure of the home is completed, all interior framed walls are installed, stairs are installed, ice and water shield is installed on the roof and the structure of the home is completely weathertight. If you choose to purchase the window and exterior door package, all windows and doors will be installed, and the home will be 100% weathertight. This is usually completed in less than 1 week.

STEP 4: ONSITE CONTRACTORS COMPLETE THEIR WORK.

After the shell kit is assembled, local subcontractors complete the rest of the home. This includes siding, roofing, electrical, plumbing, HVAC, insulation, drywall and all finishes such as flooring, cabinets, countertops, etc. These items are not part of the panelized kit. Labor and materials are provided by local suppliers and sub-contractors. These items usually need to be done by licensed professionals in your state. The subcontractors generally install their own products so they can warranty their work.

THE FINAL STEP: MOVE IN AND ENJOY YOUR NEW HOME!

You get a modern, highly efficient new home that is considered no different than any other site-built home by lenders, appraisers, building inspectors, etc. Your home is built to the same building codes and with the same building materials as any other site-built home. In addition, you get a precision-built, highly efficient home that is built up to 3x faster, with a more organized construction process and with less stress during the construction process.

PANELIZED KIT PRICING (SHIPPING NOT INCLUDED)

SUBMIT READY FLOOR PLANS, $14,900

ENGINEERING AND BUILDER PACKET

* Currently only available in Utah, Idaho, Colorado, Wyoming, Montana, Arizona and Nevada.

1. Detailed floor plans. The floor plans are designed by builders who understand how to reduce waste and simplify the construction process.

2. Structural engineering. Designed specifically for your location – snow loads, seismic, frost depth, etc.

3. Res-check energy submittal. Energy compliance information that may be required by the building department.

4. Site plan. This is specific for your lot (geotechnical and soils engineering not included).

5. Material list and “take-off” sheets. We provide a material list for the items needed to build your home.

6. Scheduling checklist. A complete checklist to help you keep track of and organize the tasks to build your home.

7. Sub-contractor work-order sheets. Sub-contractor contracts, work orders and scope of work documents.

8. Cost breakdown template sheets. Document templates Required by your bank to get construction financing

ITEMS INCLUDED:

1. Pre-framed exterior wall panels.

2. Pre-framed interior wall panels.

3. Pre-framed stairs and other structural framing components.

4. Weatherproof sheathing tape or Tyvek house wrap.

5. Pre-cut structural beams and posts.

6. Roof panels or engineered trusses.

7. Lumber to finish the trusses and roofing –sheathing, blocking, sub-fascia, etc.

8. High temp, Ice and water shield underlayment for complete roof waterproofing.

9. All labor to set the panels and complete the framing and roofing dry-in for your home.

WINDOW AND EXTERIOR DOOR PACKAGE ($36,850)

Anderson 100 series black composite windows made of Fiberex composite materials. 2x stronger and 12X thicker finish than painted vinyl.

WPC SIDING PACKAGE ($7.5O PER SQ FT)

WPC Siding (wood plastic composite) is made of real wood chips and recycled thermoplastics. This provides a natural wood look that is maintenance free, so you never need to re-stain or paint.

Traditional onsite construction is outdated. It’s slow, wasteful and less efficient than modern prefab construction methods. The advantages of our construction method are:

1. Built Faster – Generally our kit homes can be built 3x faster than a standard site-built home.

2. Less Stress – Building a house is stressful. With a panelized kit, we try to streamline the entire process from design and engineering, to setting the panelized kit, to providing documents needed to manage the rest of the construction process and finish your home.

3. Precision-Built –Panels and components are built out of the weather, in a controlled environment, using precision equipment. The result is a better-built home.

4. Sustainable – We use materials in a much more efficient manner. The result is 80% less waste than a standard site built home. This also helps keep a cleaner, more organized jobsite during construction.

PAYMENT 1: Design deposit for detailed floor plans and engineering.

PAYMENT 2 : 45% - To purchase all materials, get in the production schedule and begin construction in the factory.

PAYMENT 3: 45% - When the panelized kit is completed and ready to ship.

FINAL PAYMENT: 10% - When the panelized kit is assembled, and our scope of work is completed.

STEP 1: DESIGN AND ENGINEERING.

After you choose a floorplan, you pay the deposit for the floor plans and engineering. We then contact your local building department to determine the design and engineering requirements for your specific building lot. Engineering requirements are specific to your location depending on snow loads, frost depth, wind loads, seismic requirements, etc. We then complete the plans and engineering specific for your building location. We send you complete, submit-ready floor plans, stamped structural drawings, engineering calcs, construction documents, work orders, cost breakdown sheets, sub-contractor checklists, etc.

STEP 2: ONSITE WORK.

After the building permit is issued, your local contractor will complete all the onsite work: excavation, foundation, utility line stub-in’s etc. We provide the floor plans, engineering and instructions for the foundation and onsite work.

STEP 3: SHELL KIT INSTALL.

When your onsite work is completed, we ship and assemble the shell kit. This includes everything so that the structure of the home is completed, all interior framed walls are installed, stairs are installed, ice and water shield is installed on the roof and the structure of the home is completely weathertight. If you choose to purchase the window and exterior door package, all windows and doors will be installed, and the home will be 100% weathertight. This is usually completed in less than 1 week.

STEP 4: ONSITE CONTRACTORS COMPLETE THEIR WORK.

After the shell kit is assembled, local subcontractors complete the rest of the home. This includes siding, roofing, electrical, plumbing, HVAC, insulation, drywall and all finishes such as flooring, cabinets, countertops, etc. These items are not part of the panelized kit. Labor and materials are provided by local suppliers and sub-contractors. These items usually need to be done by licensed professionals in your state. The subcontractors generally install their own products so they can warranty their work.

THE FINAL STEP: MOVE IN AND ENJOY YOUR NEW HOME!

You get a modern, highly efficient new home that is considered no different than any other site-built home by lenders, appraisers, building inspectors, etc. Your home is built to the same building codes and with the same building materials as any other site-built home. In addition, you get a precision-built, highly efficient home that is built up to 3x faster, with a more organized construction process and with less stress during the construction process.